Introduction

The integrity of pipeline systems has never been more critical. In a world where industrial infrastructure must balance performance, compliance, and environmental responsibility, even the smallest undetected flaw can lead to catastrophic failures. Modern pipeline screening leverages advanced tools and non-destructive testing (NDT) to uncover hidden threats before they escalate into costly repairs or safety hazards.

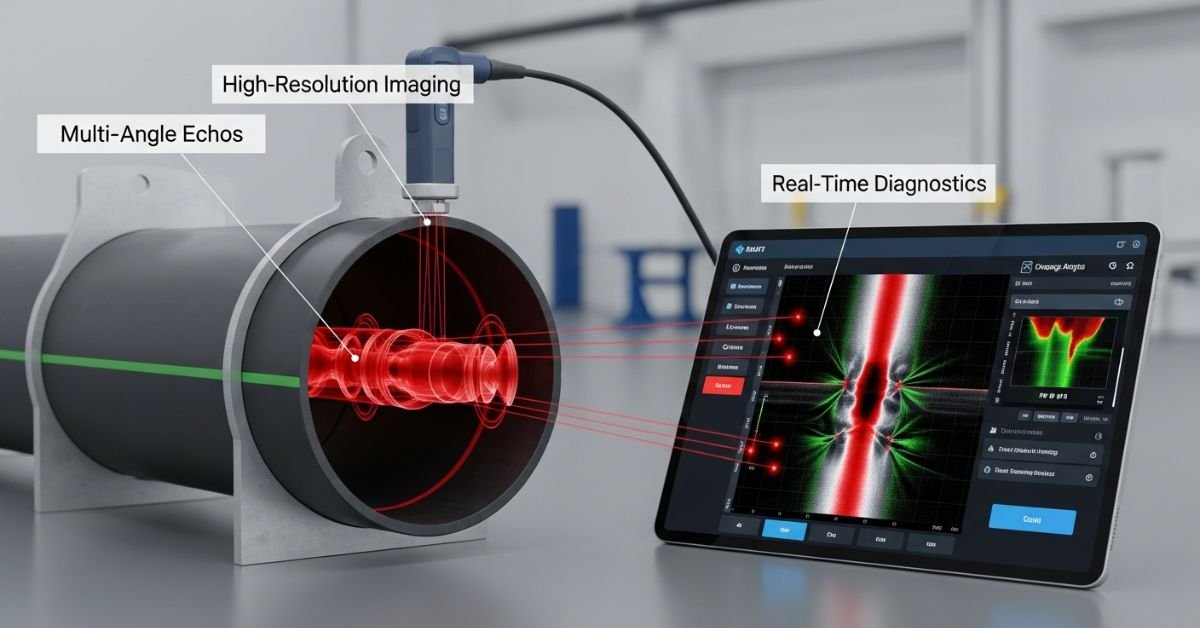

Among the cutting-edge technologies shaping pipeline inspections is Olympus Scan, a trusted solution widely adopted across oil, gas, water treatment, and industrial process piping industries. Known for its accuracy, portability, and diagnostic depth, Olympus Scan is part of a new wave of high-frequency ultrasonic testing (UT) systems designed for today’s demanding strategies for monitoring asset health.

This article dives deep into how technologies like Olympus Scan are transforming the field of pipeline screening, what professionals should know about its capabilities, and how it compares with traditional and emerging methods heading into 2026.

The Fundamentals of Pipeline Screening Techniques

Pipeline screening involves the routine and strategic inspection of piping infrastructure to detect faults such as corrosion, cracks, weld anomalies, delamination, and general wall thickness reduction. It’s a cornerstone of predictive maintenance strategies for industrial asset management.

Common Screening Methods:

- Ultrasonic Testing (UT)

- Radiographic Testing (RT)

- Magnetic Particle Testing (MT)

- Visual Testing (VT)

- Acoustic Emission Testing (AETechnique KeyeStrength CommonCommoCases UT & Deep Excellentdefects e Cases UT Wall thiwelds RT defectsOil/gaflaws elines, weldsRTDeep intepipes MT awsPressure vecracks older pipesMTSurface-level cracksWeld seams, fittings

Modern screening integrates these methods with AI-driven analysis, increasing detection rates in real time without compromising pipScan,e uptime.

What Is Olympus Scan and How Does It Work?

Olympus Scan refers to a range of portable NDT diagnostic tools produced by Olympus Corporation, globally recognized for their optical and imaging equipment. Their ultrasonic phased array devices, such as the OmniScan™ series, have been instrumental in redefining inspection standards.

Key Features:

- Phased array scanning for detailed cross-sections

- Real-time data logging and wireless syncing

- Internal visualization of flaw positioning

- Adherence to global pipeline inspection codes

The Olympus Scan system is primarily utilized for complex weld inspections, in-line corrosion analysis, and composite pipeline evaluations offehandheld-resolution imaginDevice Bestd-helCase stem.

Olympus DeviceBest Use CaseScan TypeOmniScan X3Corrosion mPLUS ng, weldsPhasthickness UT38DL PLUSGeneral wall thicknessSingle-element UT

Due to its adaptability, Olympus Scan is trusted in harsh environments where resolution and rapid feedback are vital.

Challenges in Pipeline Integrity and Early Detection

Pipelines are exposed to thermal shifts, chemical reactions, water ingress, pressure surges, and often buried environments that accelerate degradation. Regular screening is essential to maintain operational continuity and compliance.

Top Pipeline Threats:

- Corrosion under insulation (CUI)

- Hydrogen-induced cracking

- Stress corrosion cracking (internal or external)

- Weld deType s during fComplexity

ThreaCauses CUI High Moisture Infiltration ausesCPorosity Medium/faultyttechnique Microfracturing High stress andiqueMicro-fracturingHighStress + fatigue

While older analog methods lack sensitivity or speed, tools like Olympus Scan enable early-stage detection before structural compromise occurs.

Advantages of Using Phased Array Ultrasonic Testing testing

Phased Array Ultrasonic Testing goes beyond traditional UT by using multiple elements and timed pulses, creating dynamic beam angles that scan complex geometries in real time.

Key Benefits:

- Smaller dead zones (higher near-surface sensitivity)

- Faster scans across curved/irregular surfaces

- Dual-axis scans for defect sizing

- High-resolution cross-sectional imaging displayed immediately

UT TypeCoverage AreaResolutionImagingTraditional UTNarrowGoodNonePAUT (Olympus)Wide & deepExcellentYes

This technology is especially valuable during in-service assessments, allowing inspectors to run diagnostics without disrupting flow or system performance.

Comparing Olympus Scan With Competing Screening Solutions

There are several key players in pipeline diagnostics, including GE’s Krautkramer, Sonatest, and Eddyfi. Each offers unique capabilities in ultrasonic or electromagnetic inspectiFeature atureOlyScan Eddyfi/Sonatest Phasedhased ASupport Real-Time-Time 3DImaging Portability Medium-High-High SoftwareeEcosystem RobustModerateModerate eBattery Life: Up to 10 hrs Up to 8 hrs Up to 7 hrs

Olympus stands out primarily for its deep integration with analysis software and comprehensive training support, making it a favorite for inspection teams requiring consistent reporting fidelity.

Use Cases: Industries That Rely on Olympus Scan

Many industries use Olympus scan tools, particularly those where safety and reliability are paramount.

Industries Served:

- Oil & Gas: Pipeline welds, flow lines, reinforcement zones

- Aviation: Aircraft fuselage tubings and composite inspections

- Marine: Hull piping systems and ballast tanks

- Construction: Water mains and steel piping for multi-floor buildings

- Nuclear Energy: Pressure heating pipelines and valve spools

Their devices align with ISO and ASME inspection criteria, helping companies maintain compliance without excessive downtime or errors.

Exploring Data Resolution and Reporting Accuracy

One area where Olympus tools shine is data visualization and export. Their compatibility with advanced data logging systems helps engineers archive, compare, and act confidently on inspection results.

Report Features Include:

- Time-of-flight readings with defect categorization

- High-quality weld mapping views

- Digital defect logs tagged by GPS

- Instant cloud export via USB or wireless sync

By merging diagnostics with cloud platforms, teams can collaborate globally in a secure environment, another key differentiator.

Role of Certified Inspectors and Training Requirements

Operating Olympus Scan or similar ultrasound devices isn’t plug-and-play; inspectors must be certified, typically under international standards such as

- SNT-TC-1A

- Inspectors must hold either PCN or ISO 9712 Level II or III certification, as well as ASNT NDT or CSWIP certification.

- ASNT NDT or CSWIP certification

Training ensures inspectors understand beam path calibration, flaw characterization, and proper safety procedures while using scan equipment.

Skill AreaTraining Needed Certification Required Weld Inspection HighYes (ISO 9712 Level II) General Thickness Moderate (SNT-TC-1A) Automated Analysis Advanced Optional

The Environmental Benefits of Predictive Screening

Proactive pipeline monitoring isn’t just about cost, it’s about safety and environmental care. Early detection prevents:

- Hazardous material leaks

- Soil and groundwater contamination

- Long-term pipeline replacements due to undetected stress

Olympus Scan’s non-invasive technique ensures minimal ecological damage during diagnostics while encouraging companies to adopt more sustainable inspection intervals.

Future of Pipeline Screening in a Smart Infrastructure World

The future of NDT will include real-time diagnostic platforms that trigger inspections autonomously, powered by embedded IoT sensors and AI signal processing.

Key upcoming improvements:

- Smart tanks with built-in flaw detectors

- Visual AI trained on thousands of scan logs

- Drone-linked scanning for above-ground or remote pipes

- Enhanced Olympus software with multi-tech mapping (UT + EMAT)

In this digital future, high-accuracy tools like Olympus Scan will integrate with broader infrastructure management platforms transforming inspection from routine to predictive.

Table: Pipeline Defect Types and Preferred Screening Technologies

Defect TypeBest ToolDetection Method Wall thinning Olympus UT handheld PAUT or corrosion mapping Cracks in welds Phased Array + TOFDDual UT Subsurface flaws Radiography or PAUT High-resolution lens UT

FAQs

Is Olympus Scan suitable for small-diameter pipelines?

Yes, with the right probe and wedge attachment, it scans pipes as small as 1 inch in diameter.

Is training mandatory to use these tools?

Absolutely. Certified inspectors are required to operate Olympus devices in most industrial settings.

Can the scans be uploaded to cloud systems?

Yes, most devices support wireless data export or USB-to-cloud sync.

Is Olympus Scan waterproof or ruggedized?

Yes, most models are IP-rated and designed for field use.

How does this method compare to traditional radiographic testing?

It’s faster, safer, and provides instant digital results without exposure to radiation.

Conclusion

In the realm of modern pipeline diagnostics, accuracy, speed, and adaptability are indispensable. Tools like Olympus Scan are redefining how pipelines are inspected offering real-time imaging, customizable probe applications, and seamless data analysis in industries where failure is simply not an option.

As 2026 continues to set higher benchmarks in infrastructure safety and smart compliance, investing in high-resolution, portable screening solutions becomes essential, not optional. For inspection crews, engineers, and safety managers alike, mastering such tools can dramatically change outcomes on both the technical and environmental fronts.