Introduction

In today’s rapidly evolving industrial and scientific landscapes, precision matters more than ever. Whether fine-tuning a semiconductor production chamber or maintaining HVAC systems in critical facilities, vacuum measurement is often the silent backbone of operation. Selecting the right tool for monitoring vacuum pressure is not just a technical detail; it directly impacts performance, safety, and efficiency. That’s why understanding vacuum gauge types is essential for professionals navigating technologically advanced sectors.

From ultra-high vacuum (UHV) applications in nanotechnology to mid-range vacuums in food processing, the tools we use to monitor and control pressure have grown increasingly specialized. As 2026 pushes further into automation and sensor-driven maintenance, engineers, researchers, and manufacturers alike must stay informed about which gauging tools meet modern standards. This article explores various technologies used in measuring vacuum, their principles of operation, use cases, and which type is best suited for your needs in this tech-driven era.

What Is a Vacuum Gauge, and Why Does It Matter?

Vacuum gauges are devices used to measure pressure in a vacuum, a space devoid of air or gases. They’re critical in a wide range of scientific, industrial, and technological processes where controlling gas behavior is vital.

Most vacuums are categorized by pressure ranges:

- Rough vacuum: 1 to 1000 mbar

- Medium vacuum: 1 x 10⁻³ to 1 mbar

- High vacuum: 1 x 10⁻⁷ to 1 x 10⁻³ mbar

- Ultra-high vacuum (UHV): Below 1 x 10⁻⁷ mbar

Accuracy within these ranges ensures consistent material quality, reaction control, and even performance lifespans in mechanical systems.

Categories of Vacuum Gauges in Modern Technology

Vacuum gauge systems are categorized based on their pressure measuring range and the principles behind their operation.

Major Categories:

- Mechanical Gauges

- Thermal Conductivity Gauges

- Ionization Gauges

- Capacitance Manometers

- Pirani & Thermocouple Gauges

Each category offers unique performance characteristics, and selecting the appropriate one depends largely on the application’s pressure zone and environmental conditions.

An industry-wide shift to digital instrumentation has enabled enhanced feedback loops, and better integration with IoT platforms and SCADA systems.

Mechanical Gauges: Simplicity Meets Cost-Efficiency

Mechanical gauges are commonly used in rough vacuum environments due to their durability and low cost. They provide relative pressure measurements without the need for electrical power.

Common Types:

- Bourdon Tube Gauges

- Diaphragm Gauges

- Bellows Gauges

These gauges rely on elastic elements that deform in the presence of pressure changes. While they have low accuracy at very low pressures, they remain widely adopted in applications that require cost-effective, rugged instruments.

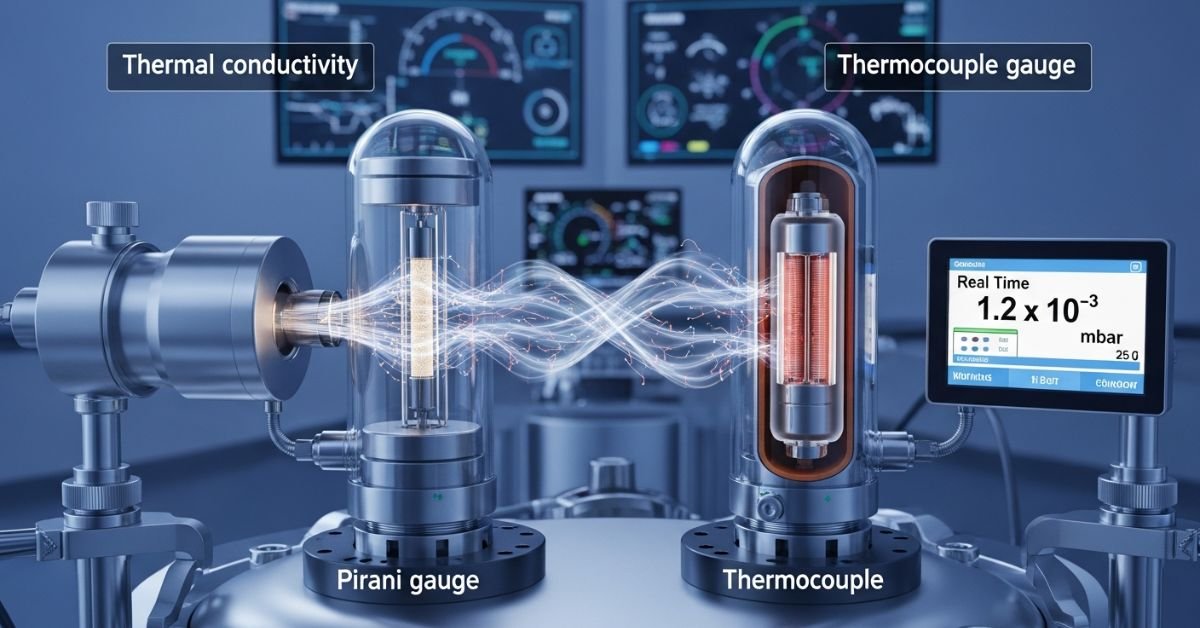

Thermal Conductivity Gauges: Gauging via Heat Transfer

Thermal conductivity gauges operate on the principle that the conductivity of a gas changes with pressure. These are particularly effective in medium- to low-vacuum ranges.

Two Main Designs:

- Pirani Gauges

- Thermocouple Gauges

| Feature | Pirani Gauge | Thermocouple Gauge |

| Sensor Heating | Electric filament | Thermocouple junction |

| Ideal Range | 1 x 10⁻⁴ to 1 mbar | 1 x 10⁻³ to 1 mbar |

| Response Time | Fast | Moderate |

Both designs are well-suited for automation, as they can be digitally controlled and integrated with modern PLC systems or remote monitoring tools.

Capacitance Manometers: Precision at Its Finest

When high accuracy is critical, particularly in industries like semiconductor manufacturing or pharmaceutical production, capacitance manometers are the preferred solution.

How They Work:

- Pressure causes deformation in a diaphragm.

- This deformation changes the diaphragm’s capacitance.

- The capacitance is then converted to a pressure signal electronically.

These gauges offer extremely accurate readings even at low pressures and are immune to gas type, a feature desirable in complex chemical or multi-gas processes.

Cold and Hot Cathode Ionization Gauges

Ionization gauges are used in high- and ultra-high-vacuum applications. They use electron beams or voltage to ionize gas particles within the vacuum chamber.

Subtypes:

- Cold Cathode (Penning)

- Hot Cathode (Bayard-Alpert)

| Feature | Cold Cathode | Hot Cathode |

| Operating Pressure | 1 x 10⁻⁷ to 1 x 10⁻³ mbar | 1 x 10⁻¹⁰ to 1 x 10⁻⁵ mbar |

| Start-Up | Needs external activation | Instant |

| Lifespan | Longer | Shorter at high temps |

Hot cathode variants provide higher accuracy but are more prone to failure due to contaminants or misalignment.

Choosing the Right Vacuum Gauge for Your Industry

Selecting the right device depends on the vacuum gauge types range you need to monitor, accuracy requirements, gas types, contamination risk, and environmental conditions.

Applications by Gauge Type:

| Industry | Most Suitable Gauge |

| Semiconductor fab | Capacitance or Ionization |

| HVAC & Refrigeration | Thermocouple or Bourdon Tube |

| Automotive Testing | Diaphragm or Digital Mechanical |

| Aerospace | Pirani + Hot Cathode |

| Vacuum Packaging | Pirani or Thermocouple |

For best results, many setups use vacuum gauge types combinations, especially in high-precision systems where overlapping ranges ensure continuity in readings.

Advances in Digital Vacuum Instrumentation

In 2026, the focus is on digitization, wireless connectivity, and AI-enabled diagnostics. Smart vacuum gauges can now self-calibrate, predict failure, and notify users remotely.

Latest trends include:

- Bluetooth-enabled sensors for portable diagnostics

- Edge computing embedded in gauges for localized data processing

- Smart dashboards that aggregate multi-point vacuum data into analytics platforms

- NFC-enabled units for mobile configuration and control

These smart upgrades significantly reduce human error and maintenance downtime, especially in manufacturing or R&D-intensive facilities.

Vacuum Gauge Calibration and Maintenance

Regular calibration ensures the vacuum gauge types maintains its accuracy over time. In fact, in sectors like pharma or aerospace, calibration compliance is non-negotiable.

Maintenance Guidelines:

- Clean sensors free of contaminants

- Avoid overpressure beyond gauge rating

- Store and transport per manufacturer compliance

- Use reference instruments for lab calibration

- Follow ISO 3567 standards for calibration intervals

Some modern sensors have auto-zero, digital recalibration, and self-diagnostic checks reducing manual workloads.

Selecting the Best Gauge in 2026: Expert Recommendations

With so many vacuum gauge types, the key is balancing cost, compliance, and accuracy. Integrated systems now allow for multi-gauge arrays centralized into one control unit saving space and providing broader monitoring coverage.

Key Considerations:

- Pressure Range Accuracy

- Gas Type Independence

- Digital Interface Availability

- Durability in Harsh Environments

- Energy Consumption

The technology continues to streamline toward plug-and-play modularity, where sensors, interfaces, and gauges function practically like USB devices—interoperable and easy to replace at low cost and minimal downtime.

FAQs

What are the most accurate vacuum gauge types?

Capacitance manometers offer the highest accuracy and contaminant resistance.

Can a Pirani gauge be used in ultra-high vacuum?

No, they’re effective only in low to medium vacuum ranges.

Do ionization( vacuum gauge types) gauge work with all gases?

They may require gas-based correction factors for accuracy.

How often should vacuum gauges be calibrated?

Calibration should occur every 6–12 months, or according to ISO/ASTM industry standards.

Are smart vacuum gauges worth the investment?

Yes, especially for industries needing automation and remote control.

Conclusion

Understanding the wide spectrum of vacuum gauge types is more than a technical requirement; it’s essential for achieving accuracy, safety, and process efficiency in 2026’s high-tech world. From mechanical meters useful in general maintenance to precision ionization systems employed in aerospace labs, the right choice can transform operational performance.

If you’re seeking to upgrade your system, consider integrating smart-enabled, multi-range tools that offer real-time monitoring and AI-supported feedback. As industries become smarter, your vacuum systems should be no exception.